April 18, 2016

(Editor’s Note: This is the first article in a two-part series examining the screen-printing industry’s ink trends. Part 2 will appear in the May 2016 issue of Impressions.)

When it comes to screen printing — specifically inks — I am often asked, “What’s new?” or “What’s trending?” My initial thoughts are, “What has been forgotten?” or “What hasn’t the customer seen?”

Then, I reflect on discussions I’ve recently had with customers, what I’ve seen in stores and what I’ve discussed with our research-and-development department.

The answers often are easy, but sometimes they’re not, because as soon as I think I have an understanding or clue of what’s ahead, I’m blindsided by what I see on the streets or retail racks.

Reflective Inks

Reflective products have been trending, something predicted to continue throughout 2016 if fashion indicators are to be believed. Glittery and shiny fabrics have recently dominated the runways and red carpets at Hollywood awards events.

Along with the standard reflective inks on the market, which usually feature a dark grey print (due to the glass beads being coated with a silver-type backing), are the enhanced reflectives that may include some type of shimmer to give the print a silvery look and more fashionable appeal. Some printers try to add curable pigments to give the reflective ink a color tone, but I recommend shying away from warmer colors like yellow and red, and sticking with cooler colors like blue and green. The warmer colors do not blend well with the silver tint of the reflective ink and the resulting mixed color tends to look muddy or brownish.

Other types of reflective inks include clears and whites, which typically are water-based. However, the reflectivity of these beads are limited since they do not have the silver-type metal backing. Printing with these inks also may take an advanced understanding of screen printing with water-based inks and additives.

One line of reflective inks has been successful, partially because of how fine the reflective glass particles are and, thus, how fine of a mesh you can use. This, in turn, allows for tiny details and halftones to be printed, which are difficult to achieve with water-based ink or other types of reflectives.

When talking about reflectives or other types of shimmers, metallics or glitters, it is important to understand the dwell time required in the dryer for the complete ink film to reach a full cure. Typically, ink that is metallic or reflective in nature reflects not only light, but also the heat needed to fuse or cure. Some screen printers raise the oven temperature and this can work, but often will expose the garment to a level of heat that may scorch or distort it if the ink is printed on polyester or a polyester blend. The added heat also can activate bleeding or dye migration.

The best way to cure a reflective or metallic ink is to reduce the speed the dryer conveyor and let the ink absorb the heat it needs to cure. This may involve reducing an electric dryer’s temperature — but not below 320°F — to avoid overheating the garment.

Glow-in-the-Dark Colors

Most recently, I’ve heard talk of the development of reflective inks that “glow,” an effect resulting from adding a phosphorescent glow-type powder to the ink.

This warrants mentioning the other hot trend gaining strength in the marketplace today: glow-in-the-dark colors. What’s more, these aren’t the traditional yellow-greenish glow-in-the-dark hues we are accustomed to seeing. Rather, they include blues, pinks and greens. The cost of these powders can be alarmingly high; thus, the addition of the glow to the reflective inks can dramatically increase costs.

When looking at these glowing colors in the dark, it can take many minutes for your eyes to adjust; as this happens, the glow may even diminish. If you can stay in the room and wait for the adjustment, you will see the glow more clearly.

To test this, I’ve “activated” a shirt (exposed it to a light source) printed with glow-in-the dark ink before going to bed. After waking up before sunrise — and not turning on any lights — I noticed I could see the print glowing from across the room because my eyes had been shut for many hours and were adjusted to the dim lighting in the room. If I had turned the light on and off, or tried to view the print immediately after coming home late at night, I wouldn’t have been able to see the print.

I often discuss costs with customers who ask me about new and trending special effects when it comes to ink. Sometimes, after such discussions, they decide to shy away and revert to tried-and-true ink products like puff, suede or glitter.

Many times, it’s not just the ink’s price that determines a print’s cost; production speeds also can put the brakes on a design or special effects. Many of these specialty inks require a slower squeegee speed to get the desired effect. They also can require additional flashes that, in turn, could require a slower throughput.

Sometimes specialty inks also can require longer cure or dwell times in the oven and higher cure temperatures, which can be problematic with heat-sensitive substrates.

However, I encourage screen printers to delve into using special-effects inks because the rewards often outweigh the initial cost factor. The benefits are twofold: First, the shop can become a go-to option for customers searching for extraordinary prints. Special-effects printing can be very lucrative and customers often don’t mind paying more for what they want.

Second, when printers play and interact with specialty inks or additives, they often will improve their skills and have a more complete understanding of the available tools and ink products. Thus, they gain a better understanding of the production costs and aim to execute prints in the most economical way. The result is that these printers become more versatile and profitable.

Kieth Stevens is the Western regional sales manager for International Coatings. He has been teaching screen printing for more than 10 years and is a regular contributor to International Coatings’ blogs. For more information, visit iccink.com and read the company’s blog at internationalcoatingsblog.com.

March 20, 2024 | Production

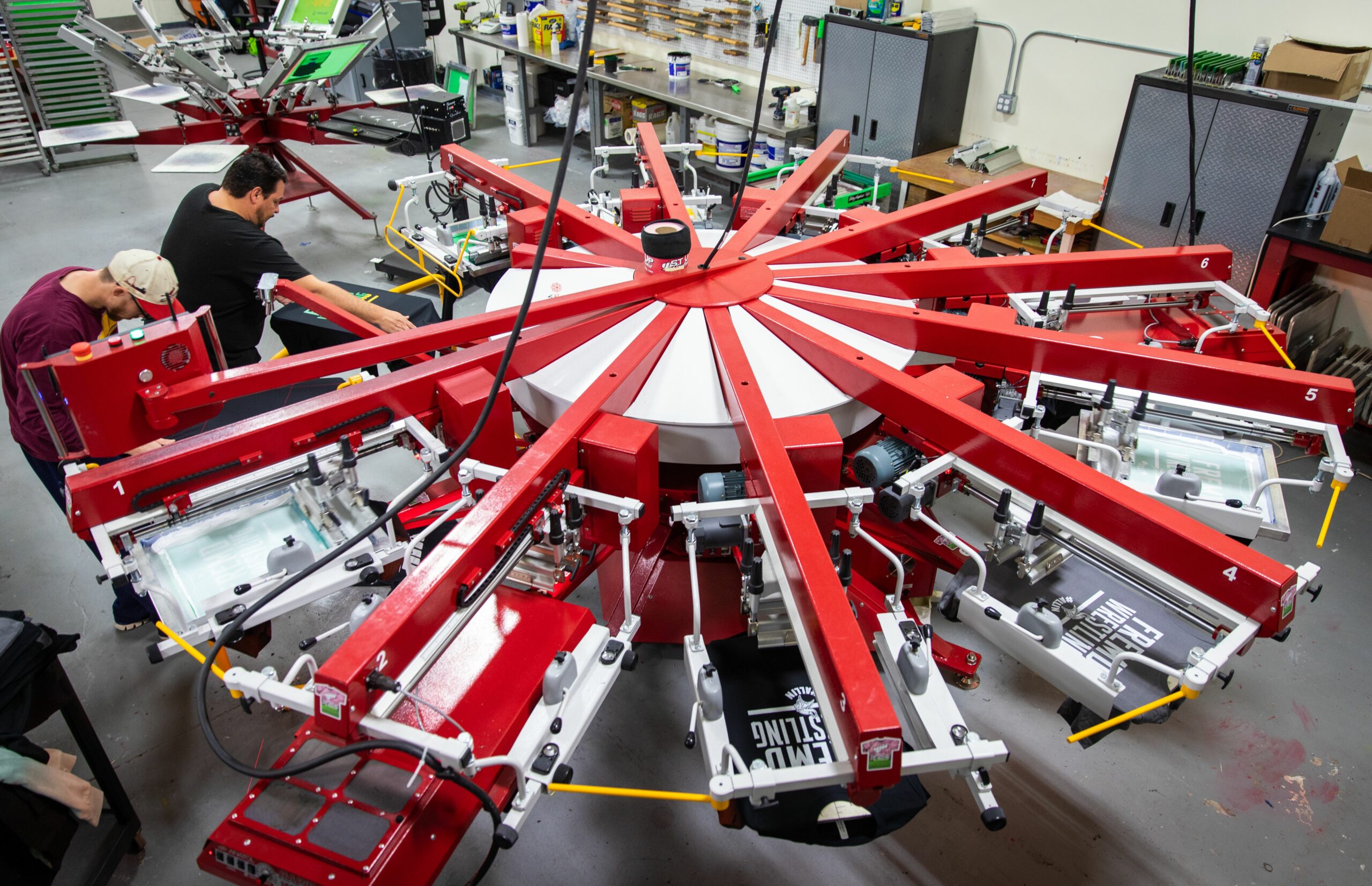

As with pretty much any business, one of the keys for apparel and T-shirt decorators running a successful custom screen-printing shop is having the right equipment, first and foremost, the right press, or presses.

FULL STORY

March 15, 2024 | Production

As is the case with flash units and dryers, screen exposure units, computer-to-screen-systems and washout booths are critical to successful screen printing of T-shirts and other apparel

FULL STORY

January 16, 2024 | Production

Go to any industry trade show or visit an actual custom apparel screen-printing shop, and your eyes will naturally be drawn to the press, or presses there. This is true whether the shop in question employs a single manual press or is running multiple autos.

FULL STORY