August 11, 2014

“Winning has nothing to do with racing. Most days don’t have races anyway. Winning is about struggle and effort and optimism, and never, ever, ever giving up.”

― Amby Burfoot

It was a crisp spring day in 2005 as my wife, Amanda, and I pulled my old tour van down a narrow steep driveway headed toward the water in Gig Harbor, Wash. On the way down, we passed a covered race transport standing on the left hand side of the driveway of a small garage shop, attached to a large house overlooking the Puget Sound.

I remember thinking that this was very different from what I envisioned the Riley Hopkins factory would be like. At the time, I had only been in the screen printing industry for about five years; but even then, I held Riley Hopkins presses in very high regard. Not only had I learned to screen print on a 1980s-era Hopkins press in high school, but I had both read and heard about their renowned quality and popularity. As I opened the door and stepped out to shake hands with Hopkins himself, an industry veteran and legend, I had no clue of the impact that meeting him would have on both of us, as well as thousands of aspiring screen printers throughout the world during the next nine years.

In 2005, Ryonet was about 1 year old and mostly sold small starter kits and tabletop screen printing presses, ranging from $300-$1,000. A Riley Hopkins press, costing thousands of dollars, seemed like an impossible sale for us to make. We knew, though, that if we wanted to become a serious player in the industry, we had to start offering higher end presses to our customers. At the time, Hopkins had just started to rebuild his business and he was ramping up to get back into the screen printing market. Most of his press components were being outsourced, with final production and assembly completed in his garage by a few helpers.

Hopkins was initially a little apprehensive about adding a startup dealer that only sold online. He knew that if he sold his presses through someone who wasn’t knowledgeable about screen printing — or who didn’t uphold the standards of his products — things would turn out badly for everyone involved. It took a few meetings and many conversations for him to become comfortable with our group, knowledge and philosophy on customer service, but he ultimately decided to add us as a dealer — trusting that we would do our part to represent his brand well.

Racing-Inspired Presses

From that first meeting in Gig Harbor in 2005, I knew that though Hopkins loved building machines, his true love was racing. He first sat behind the wheel of a race car at age 16 when he snuck his dad’s Astin Martin out for a whirl. He soon started open-wheel cars racing and eventually found himself being recruited by a Formula Atlantic team. In 1984, he entered — and won — his first Formula Atlantic race at the Laguna Seca Raceway in Monterey, Calif. There, he also met his future wife, Valerie (they are still married to this day), who was the first person to ever chew him out for not driving hard enough, Hopkins recalls. That year, he won the Formula Atlantic National Championship.

After Hopkins parted ways with his original company, Hopkins Intl., he stopped building screen printing presses for a few years. He also raced in his last professional race in 1998. In 1999, he got back into the screen printing game and started building an economical line of presses inspired by the design of his Formula Atlantic race car. I remember hearing him say that he built his presses to help screen printers “win.” They were lightweight, but very strong, which made them capable of spinning very quickly, unlike a lot of the other large presses that were built at the time. You could step up to a Riley Hopkins press, effortlessly push the wheel, and watch it spin dozens of times in perfect balance. He designed two press lines and named them after racing terms: “WIN” and “AERO.”

Everything about Hopkins, from his theory on manufacturing to his philosophy on teamwork — and even his catch phrases — had something to do with racing. I remember phrases like “Talk is cheap, lets race”, “bumping rubber”, and “Time to get back in the pits” often being used when hearing him speak about his business. Still, while Hopkins lived, loved and breathed racing, he wasn’t able to get back in the driver’s seat himself.

Fortunately, his racing-inspired philosophy behind the design and construction of his screen printing presses actually worked in application. Riley Hopkins presses changed the game for the thousands of screen printers who’ve invested in them since inception. The press sported a trendy color scheme, was affordable, compact and, most importantly, worked in the manner in which it was designed. In 2005, Ryonet went from only offering tabletop presses to selling Riley Hopkins standalone manual presses on a daily basis, rocketing the company to more than 2,000% growth in only one year.

More importantly, small- to medium-sized screen printers could finally afford the caliber of press they needed to really compete as businesses. Since that initial meeting with Hopkins in 2005, more than 6,000 people worldwide now own his presses. They have provided jobs, helped to build businesses, provided income to pay for mortgages and college tuitions, started clothing brands, printed millions of shirts and — most importantly — helped screen printers own and realize their dreams.

Back in the Driver’s Seat

Despite the impact that Hopkins’ presses had on the screen printing world, his dreams of racing were still shelved, packed away in mothballs and sitting in a moss-covered race transport above his Gig Harbor home. There they stayed, until one day in late December 2012, seven years after our first meeting. This time, I was sitting across the table with our lawyers, signing the paperwork needed to purchase Riley Hopkins Screen Printing Machines. Since our original meeting, Hopkins had often talked of selling his company to Ryonet. After all the paperwork was signed, I remember asking Hopkins what he was going to do next. With determination in his voice, he said, “I’m going to unpack my race car, lose some weight so I can fit in it again, and then I’m going to race.” I smiled, only half believing him, but excited that we were both moving forward.

As we got to work on Riley Hopkins manufacturing, moving production from Gig Harbor to Vancouver, Wash. and releasing two new models, Hopkins got busy, too. Never giving up on his dream of racing, he did all the things he needed to do to get back in the driver’s seat. This past Independence Day weekend, he pulled that same race transport into our press manufacturing plant, unloaded the same car he had won the championship with in 1984 and smiled as we applied “Powered by Ryonet” to the side of the car. We took pictures of the black and green car and matching presses sitting together. It was compelling to see the two things that defined his life displayed so intimately together: the press that had helped so many people find their dreams, and the car he was finally able to race again and live out his own dream.

Later that weekend, my boys and I met Riley and Valerie Hopkins in the pits at Portland International Raceway. He was excited and ready to race. We took our seats at the end of the first straightaway and set of turns. Goose bumps came to my skin as the flag came down and Hopkins accelerated past 160 mph. As he braked, navigated the first set of turns and flew passed a car to the left, I knew he was having the time of his life. Once more, he was racing toward his dream.

Ryan Moor is president and CEO of Ryonet Corp. For more information or to comment on this article, email Ryan at rmoor@ryonet.com.

Suggested Reading

Like this article? Read these and other screen printing articles at impressionsmag.com:

• “How to Print Numbers on Garments”

• “How to Screen Print Stickers”

April 5, 2024 | Process + Techniques

Why do we often struggle with some of the seemingly simplest things, like slathering screen-printing ink onto a decorated-apparel garment. Slathering so that it looks clean, bright, opaque and altogether attractive.

FULL STORY

March 13, 2024 | Process + Techniques

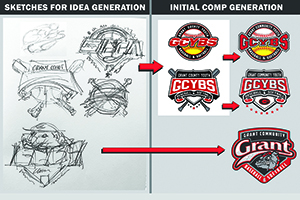

Wouldn’t it be wonderful if there was a secret formula for designing a best-selling T-shirt for a sports team, a business or for your own pre-print line?

FULL STORY

January 25, 2024 | Process + Techniques

As is the case with any craft, when it comes to screen-printing T-shirts and other apparel the devil is in the details. The best art, the best press in the world will inevitably come up short if you don’t take care of the little things as well.

FULL STORY